Leading The Trend For A Better Experience

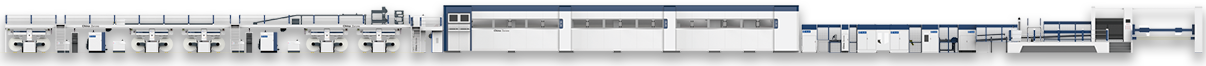

Distinctive, just to showcase the charm of intelligence. The sharp edged design of the Speed Master 300 fully showcases simplicity, brightness, and intelligence. The elegant lines of blue and white colors further unleash its intelligent characteristics; A dazzling multifunctional touchpad enable easily free fingers from buttons, with intelligent human-machine interaction to control every production moment, showcasing a high-end style; A multi perspective on-site monitoring system provides a panoramic view of the entire production process, allowing efficient production to be fully mastered. The continuous innovation of these details reflects the unique craftsmanship of the Speed Master 300, daring to take the lead in the experience.

Multifunctional Touchpad

Stylish Appearance

Monitor System

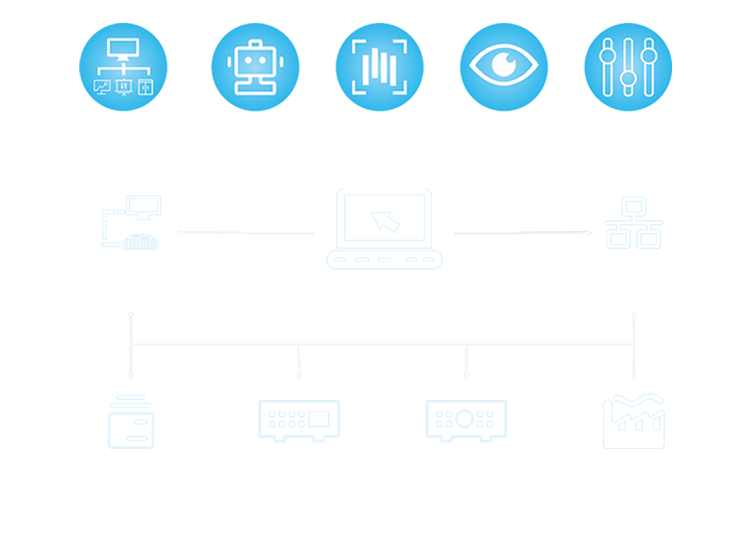

Core Technology, Forging Charm Of Intelligence

Core Technology, Forging Charm Of Intelligence Surprisingly, Speed Master 300 is equipped with a unique MES production management system and a whole line full servo control system, which intelligently schedules and distributes various types of orders, achieving seamless production execution. It can recognize the factors of the base paper or cardboard itself and automatically adjust more than ten production needs. And the surging power is transmitted through Siemens motors, while the Siemens gearbox maintains a balanced and stable speed. With excellent performance, you can easily handle various types of orders. In the blood of Speed Master 300, there is an endless pursuit of intelligence and efficiency, and a spirit of challenge to turn the impossible into possible.

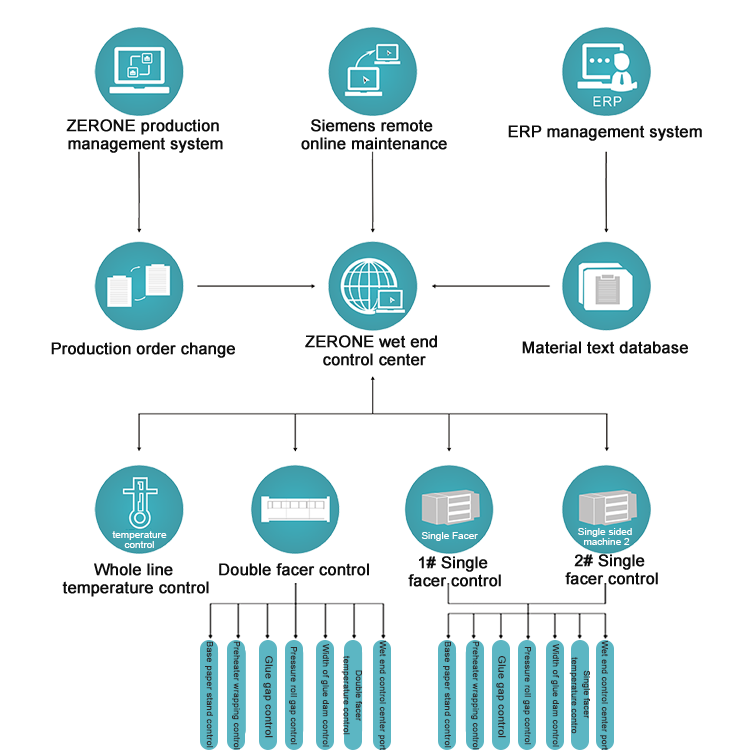

Wet End

The whole line process control system (wet end control center) independently developed by ZERONE can complete data distribution and multi segments line change control from the wet end control center to the double facer and single facer systems based on the material formula database and order letters from the production management system, thereby achieving automatic control functions during the production process; And it can intelligently recognize the humidity of the environment, the humidity of the base paper, the material, speed, and the characteristics of the glue, ensuring the quality of the base paper in the production process.

Dry End

TThe dry end control system independently developed by ZERONE, with its unique multi axis motion controller, achieves centralized control of the entire dry end system, and provides assurance for high-precision and high stability of the entire system, achieving high-speed synchronization of the entire production line, allowing you to easily cope with frequent order changes and handle various types of production orders.

Explanation: More than ten production requirements: environmental temperature/humidity, temperature/humidity of the base paper, material, speed, preheating of glue, corner wrapping, paste amount, pressure, resonance, etc.

Explanation: More than ten production requirements: environmental temperature/humidity, temperature/humidity of the base paper, material, speed, preheating of glue, corner wrapping, paste amount, pressure, resonance, etc.

I am a true speedster, unleashing passion and speed

The speed of the tile line has always been a concern, and the Subaru 300 pursues faster production speed in the process of continuous improvement. It combines the excellent Siemens full servo control system with servo motors to unleash power; The wet department and cadres are centrally and uniformly controlled, which can maintain high-speed production even when intelligently switching between different orders; At the same time, the superior performance of the mechanical equipment on the entire line makes the speed of the Subaru 300 more effortless, bringing a passionate speed of 300m/min to the entire line.

Centralized control

300m/min

One-key feeding paper

Full-speed splicing

Switch 4 flutes arbitrarily

Full line high-speed synchronization

Changing order without slowing down

250m/min

Monthly average speed

180m/min

Max stacking speed 350m/min

250m/min constant speed production of 7 continuous small orders

Energy saving and consumption reduction, creating extraordinary value

Value does not rely solely on intelligence. Speed Master 300 is equipped with an MES production management system and a full line servo control system, providing checks for energy conservation. Let energy-saving follow the cardboard like a shadow, running through the entire line.

- ◇

Automatic splicer to get the minimize losses;

-

◇

◇dopting a unique temperature control system that can automatically provide the most appropriate temperature supply according to changes in speed and material. The steam consumption of the entire line only requires 240kg per one ton of base paper. At the same time, due to servo automatic control, the power consumption rate of the entire line is far lower than the industry level to 300kw/h;

-

◇

The glue unit automatically controls the amount of glue according to different speed and materials, and adjusts the gap between the paper and the glue wheel, cutting wheel, and pressing wheel according to the speed. It keeps the paper peak at the optimal gluing point, ensuring the quality of the cardboard while achieving the effect of saving glue.

Auto-Control

Best glue point

Temperature adaptation

Steam consumption

240kg/1 Original paper

Power consumption

300kw/h