Please move the cursor

System Advantage Description

Excessive web stored on the bridge during manual operation leads to the formation of steam and extrusion deformation in semi-finished products due to poor heat dissipation, resulting in defective products such as crooked, collapsed, blister, and debonded. If there is little web stored on the bridge, it will cause pulling and unnecessary downtime, reducing production efficiency. Computer control can prevent the above issues reducing man-made consumption by 12.5%.

Based on the monthly production of 1000 metric tons of corrugated cardboard, the average consumption of manual operations is 7%, while the average consumption of computer production management is 2.5%, savings of 4.5% . In addition, manual operation cannot adjust the thickness of the glue in real-time based on paper material and speed, which can easily lead to poor cardboard adhesion or excessive glue volume, resulting in poor cardboard or starch waste. Computer production management systems can effectively reduce such waste and improve production efficiency.

Manual paper calculation relies on experience to estimate. But due to the fear of insufficient production quantity, there is usually excessive paper in the wet end, resulting in waste and unnecessary consumption. Accurate computer calculations can effectively reduce the losses and waste by 15%.

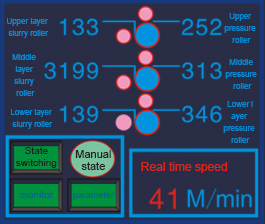

The ZERONE computer production management system can instantly calculate downtime and production speed, provide timely information and management, greatly reduce management difficulties caused by manual operations, and improve production efficiency by about 20%.

Due to the inability of manual operation to accurately control the order change time of double facer, cut-off knife, and slitter indenter, it is easy to cause waste during changing orders or flute. Computer production management systems can effectively reduce the waste.

The ZERONE Computer Production Management System provides a computer monitoring system that provides real-time consultation, improves automation, reduces personnel usage, and lowers labor costs. In addition to supporting automation on cardboard production lines, it also provides detailed records of production management data for each order, summarizes and generates various production analysis reports, provides the best consultation for managers, and maximizes production efficiency.