Congratulations on the trial operation and production of Zhejiang Jinkada 3150 Speed Master!

2025-10-21 09:05:58

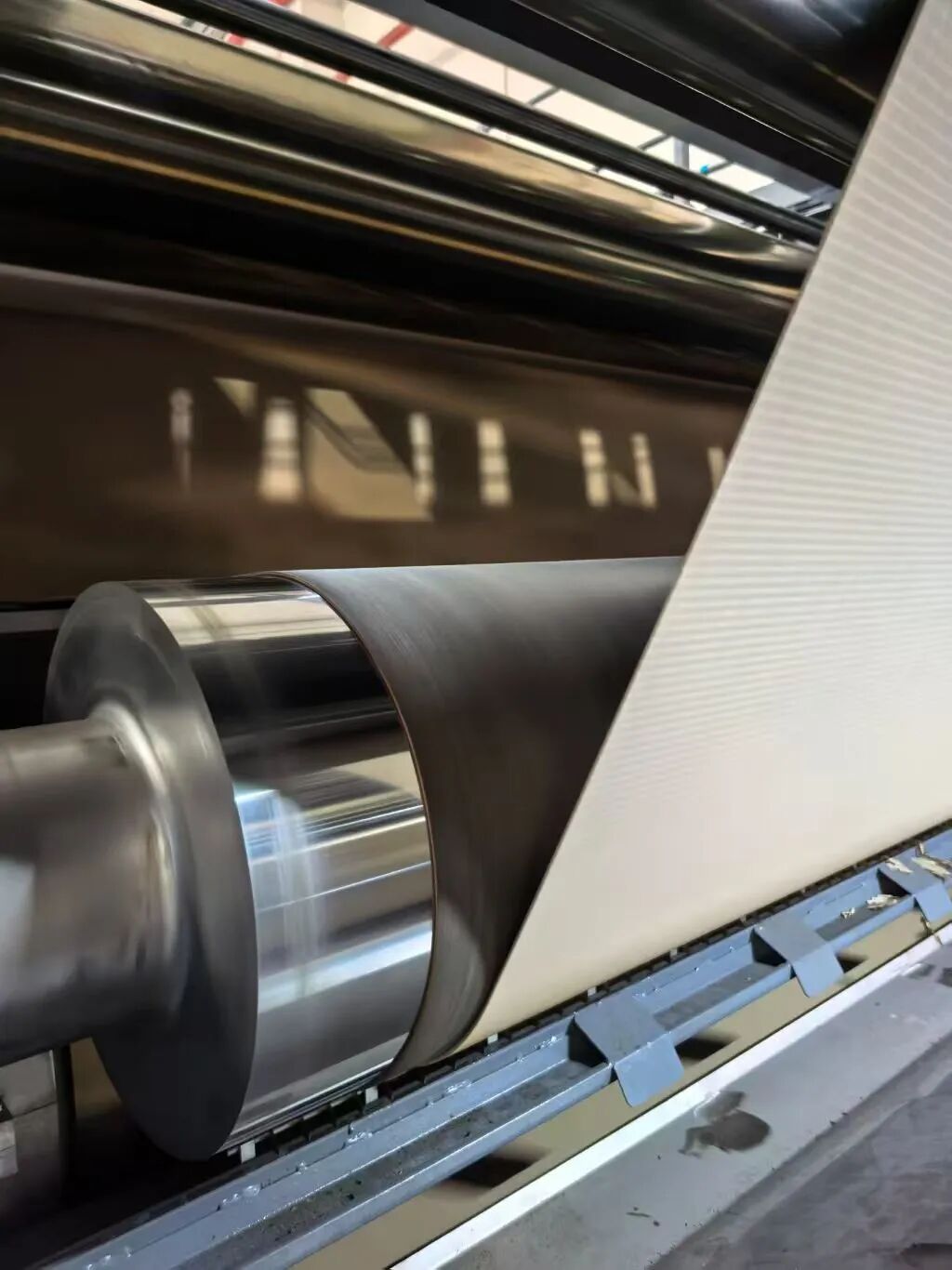

The trial production site of Zhejiang Jinkada Speedmaster intelligent tile line

Zhejiang Jinkada Paper Products Co., LTD

The total land area of the Zhejiang Jinkada project is approximately 67 mu, and the total investment in the project construction exceeds 560 million yuan. After the project is completed, it can form an annual production capacity of 100 million square meters of green packaging for cardboard and cartons, among which three-layer corrugated cardboard accounts for about 15%, five-layer corrugated cardboard about 80%, and seven-layer corrugated cardboard about 5%. Of the three-layer, five-layer and seven-layer corrugated cardboard produced, 50% each is further printed and bound into cartons according to customer requirements. The annual production capacity of cartons is approximately 50 million cubic meters, among which three-layer corrugated cartons account for about 15%, five-layer corrugated cartons about 80%, and seven-layer corrugated cartons about 5%.

Unite the strong and scale the peak together

With the strong cooperation of the teams from China ZERONE and Zhejiang Jinkada, the SpeedMaster intelligent tile production line was put into trial operation on September 29th, achieving the goal of production immediately after trial operation. This Speedmaster intelligent cardboard supply line has provided Zhejiang Jinkada with a strong cardboard supply capacity, laying a solid foundation for Zhejiang Jinkada to become an advanced and first-class modern paper packaging enterprise in East China! Maximizing the production efficiency of the cardboard production line is no easy task. It requires the effective coordination of various factors. Not only does the cardboard production line need to maintain stable and high-speed production, but it also needs to be able to meet the requirements of domestic customer orders for a wide variety of materials, short order changers, and efficient production. When it comes to high-efficiency equipment, the first thing that comes to customers' minds is definitely imported equipment.

However, after these imported devices arrived in China, they did seem somewhat out of place. In response to the complex and special order demands in the domestic market, ZERONE broke with tradition and launched a 3.15-meter Speedmaster intelligent tile line suitable for the domestic production environment.

The Speedmaster intelligent tile line that made its debut this time is equipped with the latest type of pressure strip single-sided machine. Compared with the traditional pressure roller single-sided machine, the latest type of pressure strip single-sided machine forms a continuous pressure range between the pressure strip and the heating plate, achieving the transformation from line pressure to surface pressure, and significantly extending the pressure application and heating time. This change in working principle has brought about a revolutionary performance improvement:

Outstanding corrugated forming quality

Protective corrugation type: The flexible pressure applied by the pressure strip can perfectly fit the corrugation, avoiding the wear and deformation of the corrugation top caused by traditional hard extrusion. Full corrugation: The corrugation waves produced are full and uniform, and the physical indicators of the cardboard such as edge crush strength and flat crush strength have increased by more than 10%.

Outstanding acceleration capability and stability

Due to the more thorough and stable bonding process, the equipment can still ensure the bonding quality even when running at high speed, and is less likely to "de-glue" or "bubble", providing a foundation for the high-speed production of the entire tile line.

Outstanding adaptability to paper

It can easily handle various lightweight base papers with low grammage and high strength, which are prone to crushing on traditional single-sided machines.

Outstanding ability to reduce energy consumption and costs

A higher yield rate means less waste and defective products. Stable operation reduces downtime for debugging and enhances overall production efficiency.

From the trial operation site, it can be seen that this SpeedMaster intelligent corrugated board production line is running smoothly. Not only is the production speed very ideal and reaches the expected state, but the corrugated board produced is smooth and flat with excellent physical properties, which can perfectly meet the production needs of downstream carton factory customers.

According to the plan, once the SpeedMaster intelligent corrugated board production line and the corresponding supporting equipment introduced by Zhejiang Jinkada are all put into operation, it will form a huge corrugated board production capacity, providing customers with higher-quality products and more efficient service guarantees.

With the commissioning of the SpeedMaster intelligent tile production line, Zhejiang Jinkada can provide customers with more timely and high-quality products with production equipment that is wider in width, faster in speed and more intelligent.

Sales telephone

After sales hotline

Return to the top

- Sales telephone

- After sales hotline

Huanandiqu

Zhu Shaohu:

18101611999Tan xuan:

15818396061Shi Shengjun:

18819091152

Huabeidiqu

Zhou Jiashen:

13920412188Meng meng:

13820281753

Xinandiqu

Lv Xiaohui:

13980615545

Complaints and Suggestions:18101611999(Zhu Shaohu)

Follow for more information

Huanandiqu

Guo Feng:

18819096261

Huadongdiqu

Shi Shengjun:

18819091152

Huabeidiqu

Meng Meng:

13820281753

Complaints and Suggestions:18121309992(Zhu Yu)

Follow for more information