Featuring compact structure, rich functional configurations, and minimal space occupation, it can adapt to the application requirements of frequent order changes and high-speed corrugator lines;

Separate the paper loading area from the paper return area, making it more convenient for the logistics transportation of the corrugator line base paper roll and resulting in higher efficiency;

The length of the track can be determined based on the customer's order structure and factory space;

Two paper feeding trolleys, one dedicated to paper loading and one dedicated to paper retracting;

The deceleration motor+chain drive method has higher safety and easier maintenance compared to the hydraulic motor+chain drive method, while meeting usage requirements;

Hydraulic clamping paper enables paper loading and paper roll alignment, making it easier for the base paper stand to align with the core of the base paper

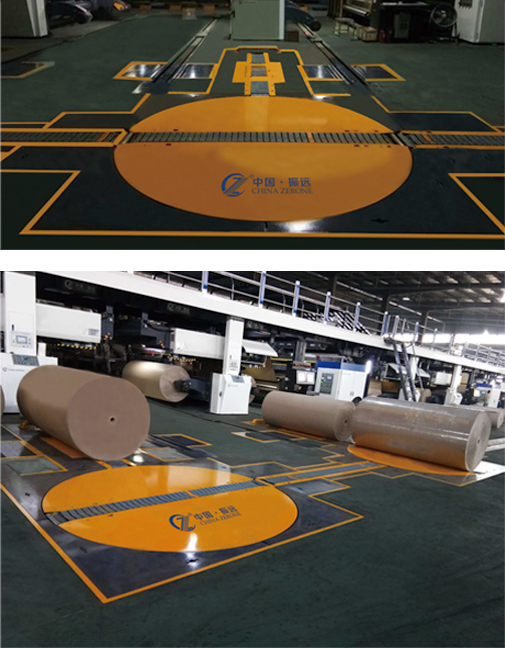

The automatic paper steering device is 90 °, which has a simpler structure compared to the electric turntable, is more convenient to install and maintain and lower cost, without additional power and energy;

Implicit pneumatic paper baffle(optional) is not easy to damage the paper roll;

Plastic chain conveyor (optional) has a simpler structure, easier maintenance, and lower cost;

Automatic base paper roll conveyor (optional) saves manpower and improves efficiency;

If equipped with a fully automatic base paper stand, it can achieve automatic loading, centering, and unloading of base paper rolls.

Trolley running speed: 17m/min;

Max supporting capacity of trolley : 4500kg;

Max supporting capacity of each retracting chain conveyor: 10000KG;

Max paper width : 2800mm;

Max diameter of hydraulic clamping paper roll: 1520mm;

Paper feeding time: varies depending on the distance between the hydraulic paper feeding and the center of the base paper stand, around 40 sec (a distance of 7.5m);

Unloading and transportation time: Based on the distance between the center of the base paper stand and the stop position of the retracting trolley, around 22 sec (a distance of 6m);

Retracting paper conveying time: depends on the length of the chain conveyor, around 6-7 min (a distance of 6m, and a length of 72m);

Operator requirements: 3-5 people, 2-3 people (automatic base paper roll conveyor)

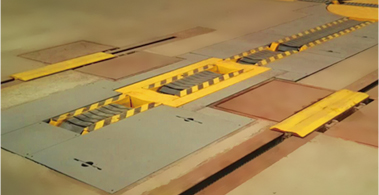

Feeding Track

Essential product for base paper stand to convey base paper;

Adopting steel plate and sheet metal for one-time bending forming, non ordinary section steel;

Made by welding, the structure is more stable;

Dual station, using imported hydraulic motors, one responsible for loading paper and the other for retracting paper.

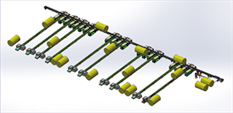

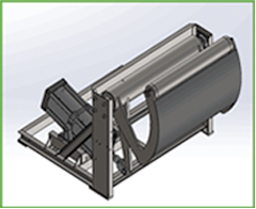

Retracting Chain Conveyor

Convey residual paper roll;

Chain conveying: breadth of each strip: 55mm; breadth of chain: 250mm; thickness 8mm;

170°V-shaped design in order to convey paper roll conveniently;

Equipped with bearings for flexible operation;

Lubricating grease is added to the cavity of the chain to lubricate the bearings, and direct pressure oil lubrication is used externally. The remaining oil in the oil cup needs to be checked regularly (usually one week);

The steel structure heavy-duty frame with unit design; helical gear reducer for transmission;

Ground tensioning method, easy to operate;

Ground invisible structure, small size without affection to other operation;

The head and tail transmission parts are equipped with maintenance machine pit cover plates, which are made of 8mm thick steel plates and easy to disassemble and assemble;

When the chain conveyor stops, the clamp truck can go through the middle section.

temporary storage and feeding base paper;

It can store two or more original paper rolls, and the paper rolls are automatically transported after use, with high flexibility;

When no paper is prepared, the entire platform can be lowered until flat as the ground, and the clamp truck can be driven on it;

Adopting independent hydraulic control for better product stability.

Split the base paper to left/right;

The overall structure is formed by welding steel in one-time, ensuring stability;

Adopting pneumatic control system, more convenient maintenance.

Align the base paper roll;

The overall structure is formed by welding steel in one-time, ensuring stability;

Adopting hydraulic control system, more stable operation and more convenient maintenance;

Capacity: Min. diameter 300mm, Max diameter 1500mm.

Align the base paper roll;

The overall structure is formed by welding steel in one-time, ensuring stability;

Adopting hydraulic control system, more stable operation and more convenient maintenance; Capacity: diameter 300-700mm.

temporary storage and feeding base paper;

It can store two or more original paper rolls, and the paper rolls are automatically transported after use;

Low cost.

Jack the residual paper roll out of the chain conveyor;

The overall structure is formed by welding steel in one-time, ensuring stability;

Adopting pneumatic control system, more convenient maintenance;

Ground embedded installation, more stable jacking.

Hidden Paper Jack

Hidden Paper Jack

Jack the residual paper roll out of the chain conveyor;

The overall structure is formed by welding steel in one-time, ensuring stability;

Adopting pneumatic control system, more convenient maintenance;

Hidden design, smaller footprint.

Retracting trolley carries the residual roll unloaded from base paper stand to the jack, during which the roll turns to 90°automatically;

The residual roll will be jacked, and stopped by the stopper, then land o the chain conveyor;

Chain conveyor delivers the residual roll to paper retracting area.

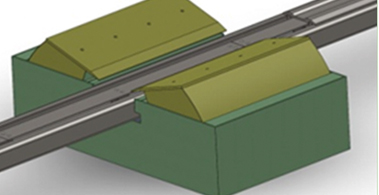

Electric Turntable

Turn the paper roll to 90°;

Equipped with chain conveyor;

Chain conveying: breadth of each strip: 55mm; breadth of chain: 250mm; thickness 8mm;

Equipped with bearings for flexible operation; no need to add lubricating oil frequently, basically maintenance free;

The steel structure heavy-duty frame with unit design;

Ground tensioning method, easy to operate; shaft type reduction for transmission;

Large outer ring gear rotation support, smooth operation and durability;

Steel cover plate of thickness 8mm.