Logistics Implementation Guarantee

The implementation guarantee of ZERONE's entire factory logistics is achieved through rational logistics management, and the overall logistics solution provided to any customer includes the guarantee of the use of the logistics system. Customers can improve their logistics operation and management level through logistics outsourcing and paid training services. We promise to provide superior logistics management solutions to our customers.

Logistics Implementation Guarantee

-

Logistics Management Training Service

Supply management scheme;

Implementation of tracking management system;

Problem improvement point tracking;

Comparison of data before and after improvement.

-

Logistics Outsourcing Solutions

Logistics packaging, tallying, and outsourcing of shipments;

5S guarantee for storage area;

Cardboard damage compensation responsibility system;

Calculation of logistics cost reduction values;

Comparison of data on improving logistics efficiency.

Logistics Hardware Equipment

A complete set of Siemens motors, frequency converters, PLC, human-machine interfaces, etc. ensure efficient logistics operation;

The logistics module structure has been optimized and designed based on European technology;

The logistics module uses imported materials from abroad to achieve long-term efficiency and durability.

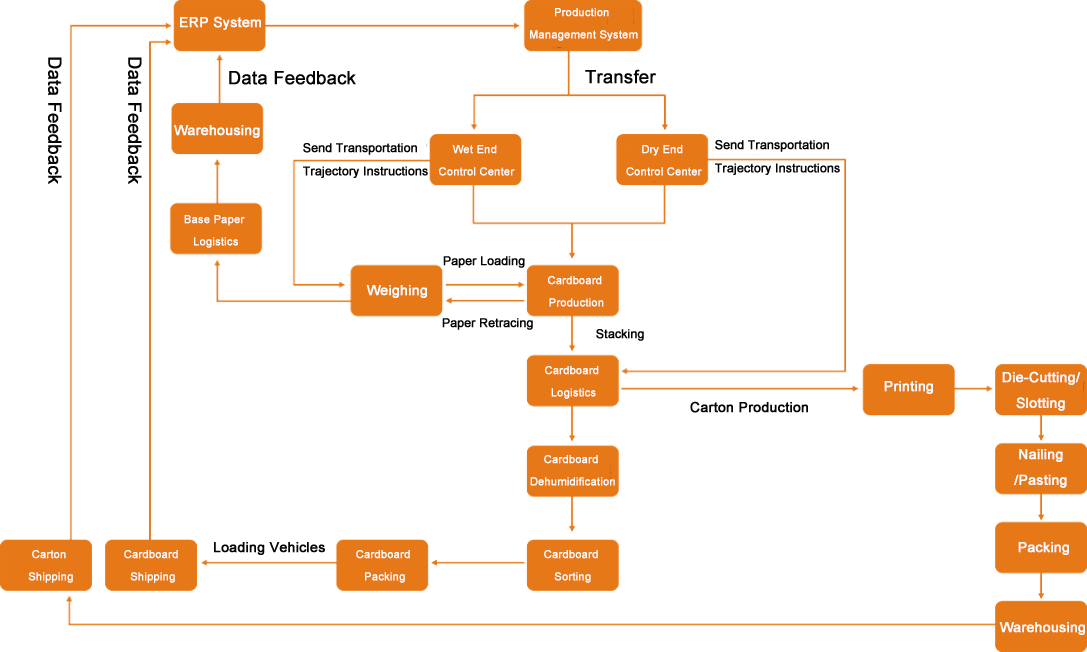

Logistics Control Software

Integrate the entire line control system, implement automated control multi-point detection

technology, ensure automated operation and integration with ERP, and improve the factory

management system.

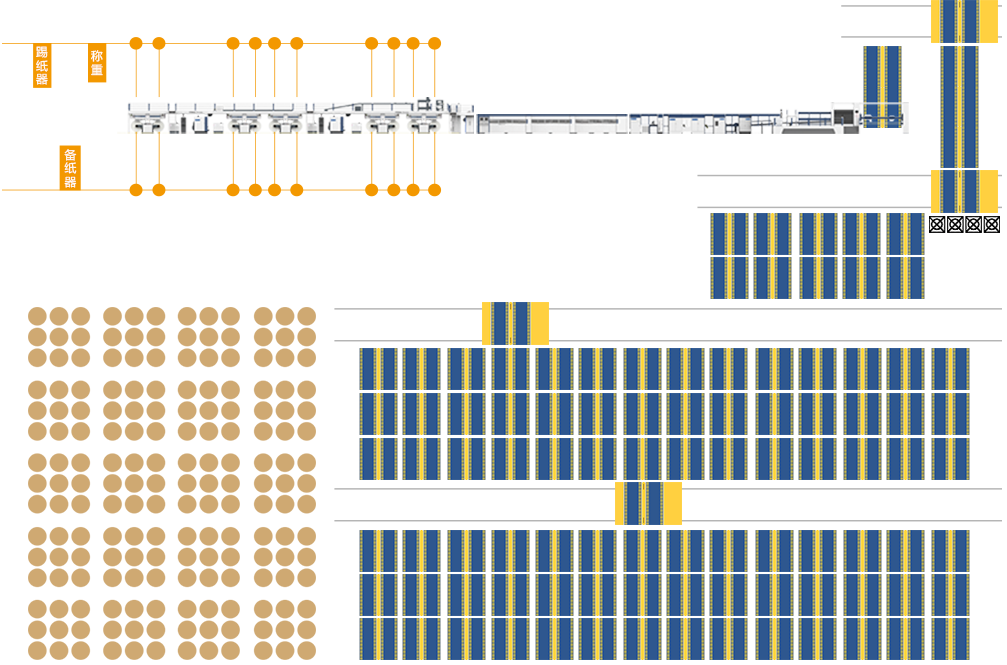

Whole Plant Layout Process Planning

ZERONE independently develops an intelligent logistics control system, with the entire hardware using Siemens motors, frequency converters, PLC, and human-machine interfaces from Germany. Combined with intelligent logistics software, it helps customers achieve intelligent control of the entire factory.

Reasonable Layout

Rationalization of order structure, improvement of production efficiency, layout of production processes, and effective utilization of space. Calculate production capacity and accurately divide logistics areas.

High Cost-Effectiveness Return

Accounting for logistics investment returns related to output value. Design personalized requirements for standard modules that meet production and shipping needs. Excellent information transmission technology and paper stack positioning technology serve as a guarantee for automation implementation.

Process Design

Optimize logistics and reduce personnel usage. Improve logistics management and increase shipping efficiency. Reasonable logistics route design ensures smooth warehousing and logistics turnover.

Whole Plant Intelligent Logistics Operation Process

Whole factory logistics, not only the displacement from point A to point B

It is more of an exploration, a discovery

In a limited space

With your burning dreams and the answers we pursue

From one starting point to the next

All are manifestations of the value of technology

Here, there is no need for manual handling Experience the changes brought by technology

No need to get stuck in traffic, enjoy every quick arrival