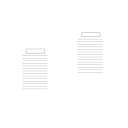

Wet End Control Center

Based on material formula database and production management system order changes, the whole line process control system (wet end control center), independently developed by ZERONE, can complete data distribution and multi segment line change control from the wet end control center to double facer and single facer systems to achieve automatic control functions during the production process; And it can also intelligently recognize the humidity of the environment, the humidity of base paper, the material, speed, and the glue characteristics, ensuring the quality of base paper in the production process.

ZERONE production

management system

Siemens remote

online maintenance

ERP management

system

Production order

change

ZERONE wet end control center

Material text

database

Whole line temperature control

Double facer control

1# Single facer control

2# Single facer control

Base paper stand control

Pre-regulator wrap control

Glue gap control

Pressure roll gap control

Width of glue dam control

Double facer temperature control

Wet end control center port

Base paper stand control

Pre-regulator wrap control

Glue gap control

Pressure roll gap control

Width of glue dam control

Single facer temperature control

Wet end control center port

According to the material recipe database and order change of production management system, wet end control system distribute data to the system of single facer and double facer on the site, achieving automatic control of production process;

Main parameters control: based on environmental humidity, temperature, material quality, speed, and glue characteristics;

Control mode: multistage linear variation

Single Facer Control System

The complete set of hardware adopts Siemens products, which operate efficiently and stably, and achieve remote online maintenance;

Siemens PLC's unique network communication technology ensures high-speed and efficient signal acquisition and transportation in single facer system;

The unique network communication technology of Siemens frequency converters ensures smooth, stable, and rapid response of single facer acceleration/deceleration operation;

Siemens PN (ProfiNet) bus makes product installation simpler, running faster and more stable;

Siemens PN (ProfiNet) bus is connected to the double facer system and dry end system to achieve synchronous control of the entire line;

Speed control, achieved through the interface of the wet end control center for synchronous control.

- A、Glue volume control: Adjust the glue volume gap through material and speed changes of the wet end control center

- B、Pressure roll gap control: Adjust the glue amount gap through material and speed changes of the wet end control center

- C、Glue dam: The width of the glue dam is automatically controlled through the wet part control center

- D、Temperature control: “Temperature sensor + material + speed change” can be achieved through the wet end control center to adjust the glue volume gap

- E、Paper stand control: automatic feeding and automatic centering of base paper

Control the amount of paper received on the bridge, with dual system control of inkjet detection and infrared measurement.

Double Facer Control System

The complete set of hardware adopts Siemens products, which operate efficiently and stably, and achieve remote online maintenance 护

Siemens PLC's unique network communication technology ensures high-speed and efficient signal acquisition and transmission in single facer systems

The unique network communication technology of Siemens frequency converters ensures smooth, stable, and responsive acceleration/deceleration operation of single-sided machines

Siemens PN (ProfiNet) bus makes product installation simpler, runs faster, and is more stable

The double facer system is connected to the single facer system and the dry end system through the PN (ProfiNet) bus, achieving synchronous control of the entire line;

Speed control: the production management achieves coordinated control of the entire line speed through the interface of the wet end control center.

- F、Glue volume control: Adjust the glue volume gap through material and speed changes through the wet end control center

- G、Pressure roll control: Automatic adjustment of pressure roll is achieved through the wet end control center

- H、Glue dam: The width of the glue dam is automatically controlled through the wet end control center

- I、Temperature control: “Temperature sensor+material+speed change” adjustment can be achieved through the wet end control center to adjust the temperature level

- J、Paper stand control: automatic feeding of base paper and automatic centering

Interface for connecting the bridge correction system.